Pilot Design

Why Pilot Design?

Designing a successful pilot is a key step in the EOR process; it is where the solutions developed in the laboratory are going to be tested at the field scale and it is often a make or break moment.

Designing a successful pilot started during the laboratory phase: the chemical formulation has to be designed correctly for the field conditions – water composition, reservoir temperature etc. But now the geology and architecture of the reservoir need to be taken into account as well. The key to success in the implementation of an EOR chemical project lies in the integration of reservoir characterization techniques, aiming at defining the reservoir and fluid response to the injection of chemicals of any origin. A simple extrapolation from core flood data to the reservoir scale (for instance in average fluid saturations calculations) is usually not valid.

Our Process

Geologist and reservoir engineers need to understand the reservoir and in particular the barriers and main conduits to flow. A pilot area will be selected so that it is representative of the field properties and if possible devoid of specific features such as faults or fractures that could bias the results.

Although it is not always possible, a pilot area should have a prior production and injection history – that allows to establish a baseline and provides the reservoir engineer with information of the movements of the fluid in the reservoir. Tracers are sometimes used to better understand those movements.

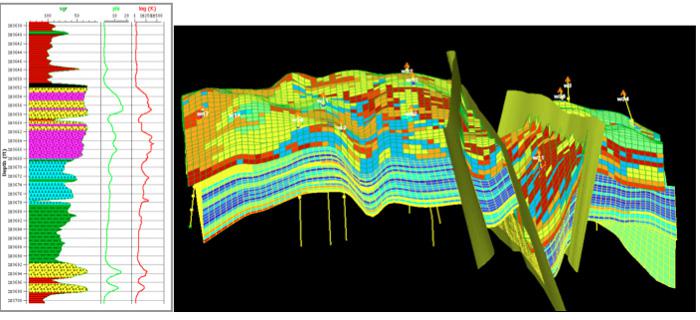

Reservoir simulation should be used to design the injection scenario and forecast the reservoir response. This is done by constructing a static and dynamic 3D model, resulting from the integration of geological, geophysical and production data. The implementation of a chemical EOR process often includes the reassessment of new rock types, with specific response to chemicals, conventional recovery would not differentiate such rock types, and the analysis of the sweeping mechanisms of the injected slugs of chemicals within the reservoir heterogeneous medium.

The integration of the past production history through history matching techniques constitutes the foundation of the EOR project, by providing the initial control of the reservoir model and fluid behavior.

The complete reservoir characterization is managed through a multidisciplinary project involving geologists, petrophysicists, chemists and reservoir engineers.

Example of rock type definition (Easytrace software) and geocellular model using the Openflow/Cobraflow package.

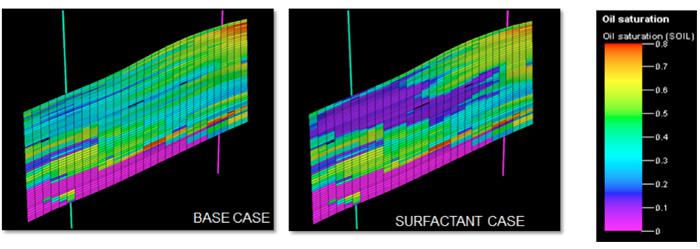

The simulations are usually done with the multipurpose reservoir simulator Pumaflow©, which offers a full choice of EOR options for Chemical Enhanced Recovery, accounting for adsorption, IFT changes, ion exchanges, combination with polymers, in simple or dual medium. However simulations can also be using other commercial software packages at the client request.

Oil saturation at 10 years after surfactant vs. Base injection pattern

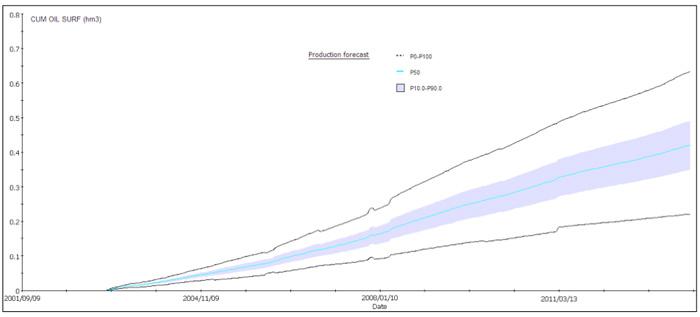

Sensitivity and risk analysis is also key to the decision process. With the help of the multipurpose Couguar™ software of the Openflow family, the uncertainties and risks associated to the recovery forecast of an EOR Chemical project can be thoroughly analyzed.

Production forecast with best guess (P50), and P10-P90 confidence

Once the pilot is underway in the field it is important to monitor closely the wells response in terms of injection and production. Water samples need to be taken periodically to monitor for surfactant and/or polymer breakthrough and observation wells are also sometimes used.

The field results need to be compared to the reservoir simulations forecast and any deviation from the forecast needs to be considered as soon as possible in order to take corrective action if necessary. At a later stage the pilot will be history matched to draw some additional conclusions and to allow for the simulation of various scenarios for the extension of the flood to other areas of the field.